Flow chart of TV production line

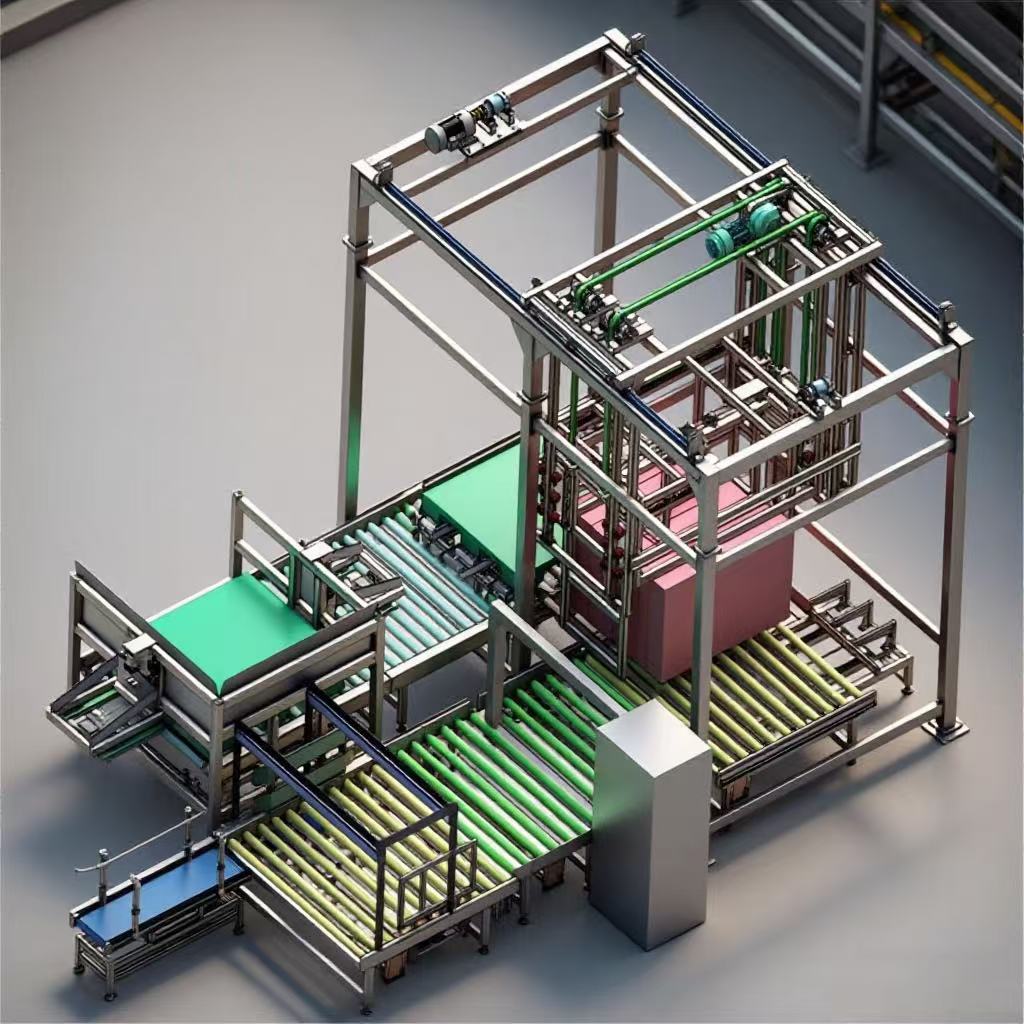

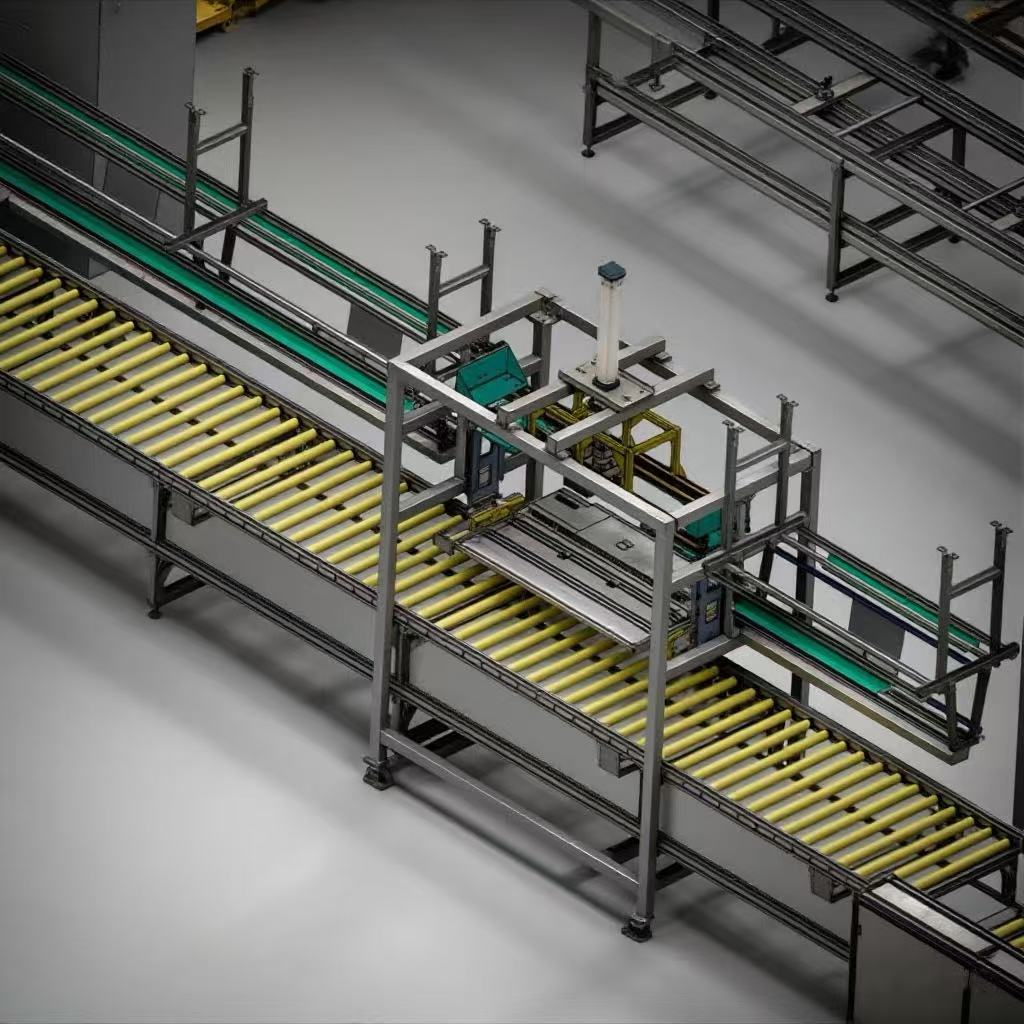

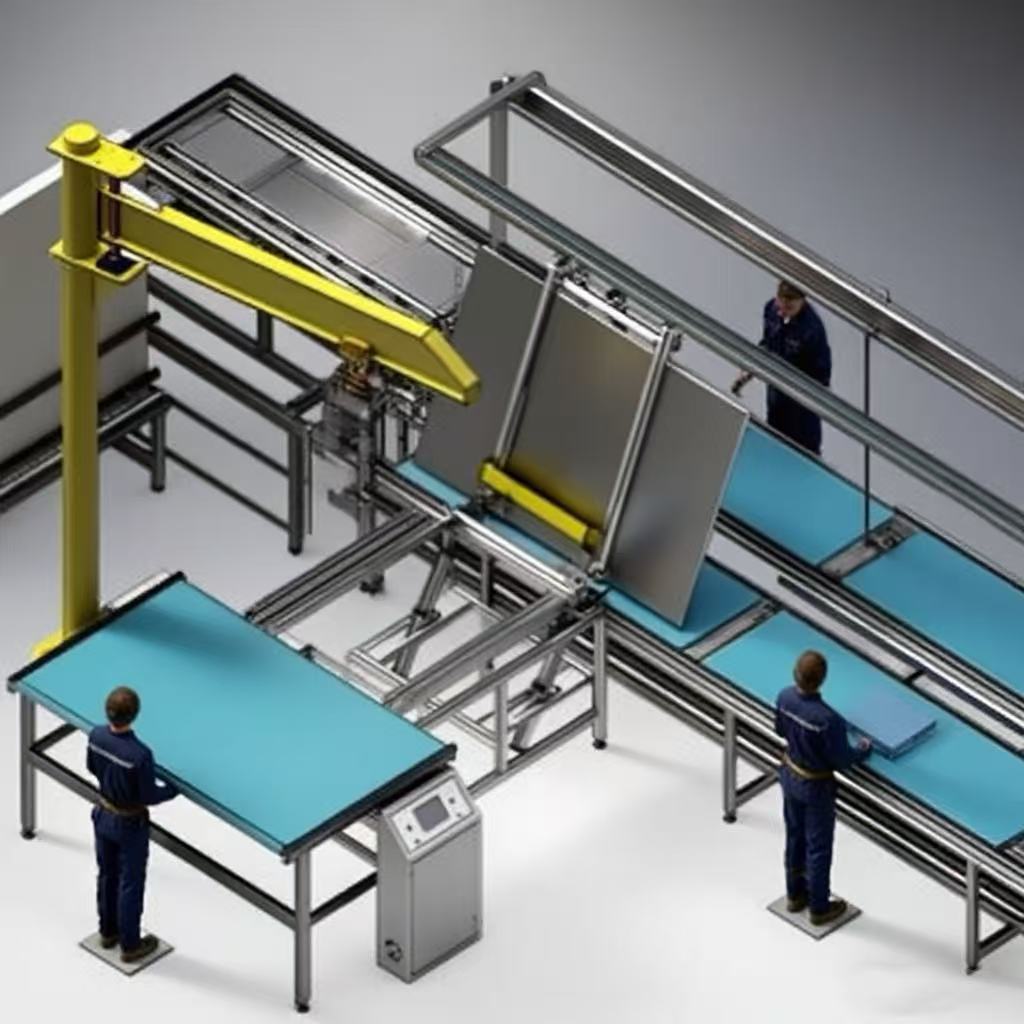

Double Drum Line (manual assembly -- Automatic Buckle of mechanical arm -- automatic buckle of mechanical module front frame glass -- manual assembly) -- automatic line change (mechanical arm or module type) -- automatic turnover (rolling machine) -- Single Belt Line -LRB-complete machine assembly) -- pre-test (automatic vertical machine) -- line change (automatic vertical machine) -- aging line (multiple speed chain line) -- automatic down line (mechanical arm) -- packaging line (drum line) -- palletizing (mechanical arm)

At the end of the production process, automatic packaging equipment can efficiently complete the packaging of the finished product, ensuring that the motor is not damaged during storage and transportation. Common equipment includes the following categories:

Automatic Carton opener: can automatically complete the carton reclaimer, molding, folding, sealing and other operations, according to the size of the motor to quickly adjust the carton specifications, every minute can open 10-20 boxes, instead of manual folding carton tedious process, greatly improve the efficiency of the preparation before packaging.

Automatic Packing Machine: equipped with visual positioning system, it can accurately grab and detect qualified motors, put them into cartons according to preset arrangement (such as single row and Double Row-RRB- , and adapt to the packing needs of different types of motors, positioning accuracy, to avoid the collision of artificial packing damage.

Automatic sealing machine: through the tape or hot melt glue on the motor packed carton sealing, can be completed at the same time up and down sealing, sealing speed and packing machine matching, to ensure smooth and firm sealing, to prevent the cartons scattered during transport.

Automatic winding film machine: for batch motors that need pallet (pallet) transportation, it can automatically wind the winding film on the stacked motor pallet, and form a solid overall packaging by adjusting the winding tension and number of turns, enhance the stability of the stack, to resist the turbulence in transportation.

Automatic labeling machine: automatically labeling on the surface of the motor or carton. The label can contain information such as model, batch and production date. It supports data synchronization with the MES system, ensure that product traceability information is accurate.

These packaging equipment can be connected to the end of the motor assembly line, through the conveyor belt to realize the automatic flow of materials, forming a"Assembly-detection-packaging" of the whole process automation, reducing manual intervention, while improving the packaging efficiency, ensure the standardization and safety of the motor packaging.